If you are in the food and drink business then you will require an ice machine. Whether you are a pub/bar restaurant hotel social club or café and ice machine will be an absolute must. The main reason for any outlets need for an ice machine will be to add to drinks, however in food led establishments ice can have a variety of uses, blanching vegetables, buffet displays, but drinks will be the primary use. It’s not as simple as finding any old machine that will freeze water though. You might be surprised at just how many options there are and all the factors you should consider to find the best ice maker for your needs.

If you are in the food and drink business then you will require an ice machine. Whether you are a pub/bar restaurant hotel social club or café and ice machine will be an absolute must. The main reason for any outlets need for an ice machine will be to add to drinks, however in food led establishments ice can have a variety of uses, blanching vegetables, buffet displays, but drinks will be the primary use. It’s not as simple as finding any old machine that will freeze water though. You might be surprised at just how many options there are and all the factors you should consider to find the best ice maker for your needs.

With some notable exceptions (hot tea, coffee and beer, for instance), most drinks only feel right if they come with ice. Ice adds sparkle and profit to all sorts of drinks, from soft drinks, G&T’s, cocktails (and mocktails), to iced coffee, with ice machines now offering a plethora of different shapes and sizes of ice. “With the summer season approaching it’s more important than ever for operator’s to offer impressive and intriguing chilled drink selections in order to increase sales.

Cocktails and mocktails, for example, welcome an impressive array of colours, tastes and textures onto the drinks menu, and when it comes to producing quality profitable drinks that both look and taste amazing, ice plays a pivotal role. As well as being used to chill the beverage or the glass itself, ice can be used within the mix itself, being shaken, stirred or crushed in order to create various textures.

Thanks to innovation in ice making technology, operators now have the choice of an array of ice varieties by the touch of the button meaning operators can easily offer a wider assortment of authentic drinks with varying textures.

The four most popular types of ice produced by commercial machines are cube, flake, bullet and spray, each with their specific benefits within business sectors.

• Flaked Ice is ideal for chilled displays And buffets, keeping foods cool and prevents foods such as fish from receiving “freezer burn”, as the ice can be used as a cool bed, shaping itself around containers and storage trays. It is also used in the production of cocktails, mocktails and smoothies, as it reduces wear and tear on blender blades.

• Bullet Ice can be used for both of the above a and is generally produced a little faster than cubes, however it can tend to melt faster than typical cubes due to the speedy way the ice is produced. Bullet ice is sometimes called “chewable” ice as it is softer and easier to blend – useful for the healthcare or childcare sectors. Bullet ice is commonly produced by manual fill ice makers.

• Spray Ice is generally considered the best quality ice. Perfect for top-end banqueting or occasions, this ice is crystal clear and takes much longer to melt in comparison to other types. However, spray ice machines can take longer to make the ice, so you need to ensure you select an appropriate machine to meet your expected demand.

As a busy season approaches, making sure that you choose the right commercial ice maker for your establishment can be a critical decision. Here are some simple guidelines to follow to ensure that your investment becomes an invaluable addition to your business.

The four main factors to consider are:

• Ice type

• The space you have available or the positioning of your ice machine

• Budget

No business wants to be stuck with a bigger machine than they need. On the other side of the cube, an undersized machine can be equally disastrous; leading to an “ice shortage”, unsatisfied customers with lukewarm drinks, and improperly chilled food that wilts alongside patron loyalty. Again, a potentially devastating to the reputation to your business. Furthermore, no business has a limitless budget. You do need a commercial ice machine that fits all your needs, but you have to find the one that fits in your price range.

Beyond looking at the price of the ice machine itself, you need to consider all the other costs that relate to making ice: the water usage, the energy usage, installation costs, storage accessories and water filters, to name a few.

Ice machine experts Maidaid recommend finding out what style of ice would best fit the sites requirements.

Selecting a suitable location and ensuring there is sufficient space available is vitally important. A few questions that need to be answered are as followed; Make sure the environment does not exceed the air and water temperature limitations for the equipment. And that the necessary utilities are available including the correct voltage electrical supply. The last thing that is often forgotten is the space around the machine for service, 15 cm. minimum left, right, and rear for air-cooled models is recommended. Cellar installs will effect change the ambient temperature throughout the seasons, resulting in a dramatic change to the machines performance.

Some of the biggest mistakes operators make is expecting the machine to produce crystal clear ice when the machine has a poor water supply and filtration.

To achieve the best results from any Maidaid Icemaker it is important that the machine is supplied with high quality water. To achieve this it is strongly advised that from installation the machine is installed with the correct filter and softener. An experienced distributor will be able to advise what is best for the machine selected. To maintain high quality ice being produced Maidaid advise that all filters and cartridges are replaced every 6 months dependent on water quality & usage, this will prevent the ice maker suffering from premature breakdown due to scale.

To achieve the best results from any Maidaid Icemaker it is important that the machine is supplied with high quality water. To achieve this it is strongly advised that from installation the machine is installed with the correct filter and softener. An experienced distributor will be able to advise what is best for the machine selected. To maintain high quality ice being produced Maidaid advise that all filters and cartridges are replaced every 6 months dependent on water quality & usage, this will prevent the ice maker suffering from premature breakdown due to scale.

One of the most common maintenance issues with Ice machines is the blockage of the condenser due to dust and debris build up. This is easily rectified by cleaning the air inlet grills with a vacuum and a soft brush. Ensuring Water supply filters and softeners are replaced will help to ensure the longevity of the machine and maintain hygiene.

Operators can ensure that their ice makers continue to produce high quality ice by regularly inspecting and following the cleaning regime. Not only is it imperative to clean the ice maker itself but it’s also importantly to regularly clean the storage bin, door and even the ice scoop, this will help to prevent ice contamination. Regularly completely refreshing the ice in the storage bin especially in low usage establishments will also help to achieve a consistent high quality ice cube

In the interests of hygiene, Maidaid Halcyon are now including a ‘wash hands before use’ label with every Ice Maker supplied, which they suggest is applied to the bin lid where it will be visible to all users.

Roz Scourfield, National Sales Manager at Hoshizaki UK comments, “As the variety of beverages consumed grows and the popularity of specialist spirits and cocktails continues to advance, the type, consistency and quality of the ice used on a drinks menu is vital, and getting this right can mean the difference between customers staying house, and those heading out to drink in other establishments. Innovation in ice making technology has led to the creation of a whole host of different machines and styles, with operators now having the choice of many finishes including cubed, flaked and more recently ball ice. Choosing the correct type of ice depends very much on the beverage offering, but in essence, the larger the individual pieces of ice, the slower it melts and therefore the less dilution occurs – something that is key for many spirits and cocktails found on most beverage menus.

Roz Scourfield, National Sales Manager at Hoshizaki UK comments, “As the variety of beverages consumed grows and the popularity of specialist spirits and cocktails continues to advance, the type, consistency and quality of the ice used on a drinks menu is vital, and getting this right can mean the difference between customers staying house, and those heading out to drink in other establishments. Innovation in ice making technology has led to the creation of a whole host of different machines and styles, with operators now having the choice of many finishes including cubed, flaked and more recently ball ice. Choosing the correct type of ice depends very much on the beverage offering, but in essence, the larger the individual pieces of ice, the slower it melts and therefore the less dilution occurs – something that is key for many spirits and cocktails found on most beverage menus.

As with refrigeration and freezer equipment, there are certain aspects that must be considered when specifying an ice machine. For example, in order to operate efficiently, operators must position their ice making equipment in a space that has good airflow as well as one that has access to relevant utilities including water, electricity and waste. Where waste is concerned, it is important to check that the flow is suitable for the size of the machine and identify whether a pump is required.

When it comes to the style and type of ice, it is important that the operator understands the volume of ice required and ascertains what the primary use of the ice will be. For example, if an operator needs to start the day with say, 20 kilos of ice for a display and further smaller quantities for use, an operator must purchase a machine that is able to produce and store sufficient ice overnight.

Finally, we recommend that operators look at the quality of the ice as much as the quality of the machine. As a global manufacturer of quality cold solutions, we pride ourselves on producing outstanding ice, with unrivalled clarity and consistency.”

IS THE ICE YOU’RE SERVING ALL IT’S CRACKED UP TO BE?

IS THE ICE YOU’RE SERVING ALL IT’S CRACKED UP TO BE?

According to the latest research by ice machine manufacturer, Ice-O-Matic, it may not be… In a survey undertaken amongst foodservice professionals a surprisingly high number of operators did not clean their ice machines regularly as per manufacturer’ recommendations. And 40% didn’t know how often they did – or, how often they should – clean their machines.

Adam Lenton, Marketing Manager for Ice-O-Matic UK, explains the impact this can have on the ice served:

“Ice is a vital component of many drinks and should never be taken for granted. The majority of operators are diligent around the cleanliness and quality of their ice but the fact remains that a worrying number of caterers did not clean their machines as often as they should and had limited knowledge around what is acceptable or what the manufacturer recommendations actually are….

“Poor levels of hygiene in ice can affect consumers as badly as those from poor food hygiene practices. Proper and regular cleaning is vital.”

Ice-O-Matic’s research also went onto find that around a third of consumers have concerns when it comes to the levels of bacteria that may be present in the ice they get served when dining and drinking out, with over 30% saying it put them off having ice altogether.

Lenton adds, “Some consumers do not like ice period. We know that some have sensitive teeth, others who feel that ice dilutes the drink. But, let’s not forget that around 70% of those asked, want to be served ice and love the refreshing impact it gives them.

“Operators simply have to keep on top of the problem and manufacturers can help too. For example, we offer a ground-breaking device – the 03-Matic (Ozone) which infuses ozone into incoming water, killing microbes on every surface it touches and retarding future growth to diminish mould, mildew, bacteria and viruses.”

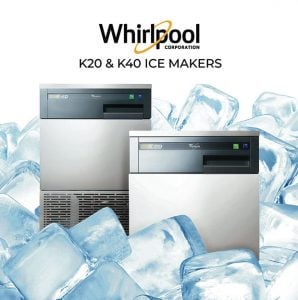

Whirlpool believe that functional simplicity is key when choosing an ice machine.

Manufactured for over 30 years, the Whirlpool K20 and K40 remain a popular choice, being both easy to use and easy to maintain. They produce clear cubed ice in just 17 minutes and the robust stainless steel construction is a must in the busiest bar or kitchen. Safe, simple, hygienic and reliable, they benefit from not having complicated controls and electronics which are more prone for failure. Their simple, user friendly operation makes them very popular with community centres and small clubs.

Whirlpool understand the importance of aftercare in keeping businesses up and running and their industry leading speed of service highlights just how seriously they take this. If they cannot get an engineer to site within 72 hours, or the parts required to fix are not available they will replace the machine. This high level of confidence in their product gives businesses peace of mind.

Whirlpool recommend the use of an inline water filter to ensure optimal ice quality and retailers such as Alexanders Appliances Direct opt to provide a filter with every unit to ensure the best performance for the customer.

PURCHASING

1. Select a machine with a tight fitting door compete with

a gasket or seal.

2. Look for an ergonomically designed ice bin with radiused or rounded corners and with all areas visible and accessible.

3. Avoid any machine that has interior joins, cracks or crevices in the ice bin.

4. Look for a machine offering a rinse and flush cycle between each ice cycle, thus helping to eliminate water residues.

5. Demand a substantial warranty. If a manufacturer is confident in a machine’s quality, this will be provided automatically.

MAINTENANCE

1. Ensure all staff are aware of the dangers of contamination and understand how to prevent it.

2. Empty the ice bin completely at least once every week to clean and sanitise with a proprietary cleaning fluid such as Milton and rinsed thoroughly.

3. Ensure all objects in touch with the ice – such as scoops, tongs and buckets – are also treated.

4. Move ice storage vessels away from customer reach.

5. Keep regular checks to make sure the machine is in good condition – especially the door, as broken or loose fitting doors are one of the most common faults to occur on ice makers.

classeq.co.uk/elevation

www.alexanders-direct.co.uk

www.hoshizaki.uk

www.maidaid.co.uk