Cleaning Machines – The Latest in Warewashing

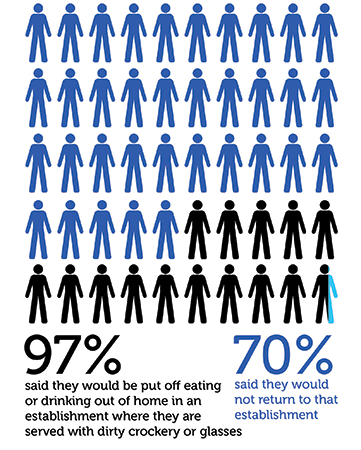

When customers visit any pub/bar or restaurant they expect, nay demand high standards in quality of food and drinks, service, cleanliness, hygiene, and that is particularly so when it comes to the standard of cleanliness of the crockery or glassware, so it’s vital that operators can rely on their cleaning equipment to get the job done.

When customers visit any pub/bar or restaurant they expect, nay demand high standards in quality of food and drinks, service, cleanliness, hygiene, and that is particularly so when it comes to the standard of cleanliness of the crockery or glassware, so it’s vital that operators can rely on their cleaning equipment to get the job done.

Furthermore, with sustainability and economy top priorities in the hospitality and on-trade sector, operators want warewashing equipment that minimises water, fuel and chemical use, saving money and the environment. The hospitality sector relies heavily on its warewashing machines to deliver reliable and consistent levels of cleanliness to maintain a steady supply of clean glassware and crockery.

Consistency is therefore a vital quality, given that broken-down machines mean slow service leading to lost revenue.

While exact requirements will vary from outlet to outlet, equipment manufacturers advise that there are some key considerations for any operator to help them ensure their crockery or glassware doesn’t let them down, leading to negative comments “in the court of public opinion” that is TripAdvisor!

Risking the wrath of a customer for any pub/bar or restaurant can disastrous consequences, social media has made it easy for a dissatisfied customer to vent their dismay not only to friends and family but to potentially the entire online world. Added to that, budding food photographers snapping every meal they see and adding location information to each image your establishment’s reputation is constantly being examined, and re-examined. Reducing the risk of a bad review is paramount.

The “Space war”

In recent years there has been a shift to smaller more compact kitchens, but smaller kitchens are coping with the same levels of service, in some cases some smaller kitchens have seen significant increases in output. This is also evident in bars, particularly with the rise of microbreweries leading to a constant battle behind the bar between new products and glasswashing equipment.

In recent years there has been a shift to smaller more compact kitchens, but smaller kitchens are coping with the same levels of service, in some cases some smaller kitchens have seen significant increases in output. This is also evident in bars, particularly with the rise of microbreweries leading to a constant battle behind the bar between new products and glasswashing equipment.

This, of course, presents a challenge for those responsible for purchasing equipment, but one that manufacturers have strived to make simpler by creating slimline versions of their equipment.

With the large amount of soiled cutlery, crockery and glassware that a busy establishment can generate it’s imperative you have equipment you can rely on, and one that’s suits your operation and budget. Warewashing manufacturers and distributors are increasingly called upon to provide advice almost all will agree that while owners of new or existing outlets are seeking ways to increase efficiency and reduce their footprint to create extra room for commercial purposes, you simply cannot compromise too drastically on space for warewashing.

Many of the decision criteria to be considered are the same for any type of glass or dish washing, says Julian Lambert, Maidaid Halycon’s former Sales Director: “ Firstly customers need to identify what they need to clean and the time frame for the cleaning process, do they have a continual through put of product and are there peak times of activity. Do they need to have a machine with the capacity to deal with peak demands or can the site process at a steady rate? What mix of product are they going to wash, plates, bowls, glasses and service trays?”

“Other major considerations are the space available and services – water supply and power are convenient for installation. When purchasing a hood machine, space for prewashing and unloading tabling must be allocated and be of sufficient size to enable operators to use the machine effectively. On too many occasions Maidaid have received requests to down grade machines power requirements after the machine has been delivered due to insufficient power being available, this consequently means the equipment can never function to its full potential. If the operator is not experienced with the requirements then a site survey by an experience distributor should be arranged prior to placing an order.”

David Glover at Wexiodisk, who have announced the expansion of their glasswasher portfolio with 4 glassware specific hood-type models, says that despite being an essential part of a kitchen set-up, warewashing can often fall behind in an operator’s list of buying priorities, perhaps because it is associated with cleaning rather than catering.

David Glover at Wexiodisk, who have announced the expansion of their glasswasher portfolio with 4 glassware specific hood-type models, says that despite being an essential part of a kitchen set-up, warewashing can often fall behind in an operator’s list of buying priorities, perhaps because it is associated with cleaning rather than catering.

“This failure to prioritise warewashing, however, makes creating an effective and efficient warewashing flow particularly challenging, especially within compact kitchens where space is at a premium.”

In order to avoid these issues, Glover recommends that operators elevate the purchase of warewashers to the same level they would, or higher, for any other essential piece of kitchen equipment, such as a refrigerator or oven. “In fact, some of the most efficient kitchens start by prioritising the warewashing area in which they can design a seamless warewashing flow according to the space and shape of their kitchen,” he says.

The Clean Solution for Coronavirus

Hygienists have confirmed that dishes are free of the coronavirus after one wash cycle in a Meiko dishwashing machine.

Hygienists have confirmed that dishes are free of the coronavirus after one wash cycle in a Meiko dishwashing machine.

The cleaning and disinfection performance of Meiko cleaning and disinfection machines has now been assessed as highly effective against SARS-CoV-2 by an independent hygiene institute, Hygcen Germany GmbH. The report compares the temperature, mechanism and use of chemicals in Meiko appliances with the established characteristics of coronaviruses. The results: the cleaning process used in Meiko cleaning and disinfection machines is safe.

There are, however, a few extra points to remember when dealing with potentially contaminated care utensils, such as bedpans.

Add an alkali detergent to the hot cycle: Numerous tests have shown high efficacy in combating viruses with envelopes, in particular using detergents with high emulsifying capacities and hot alkali-detergent solutions at 50 °C or higher. Coronaviruses fit into this category. This is always an option with Meiko products as it is possible to add an alkali detergent to the hot cycle.

On bedpan washing machines, set the disinfection cycle to an A0 value of at least 600: An A0 (thermal disinfection) value of 600 is considered sufficient to disinfect surfaces of temperature-sensitive viruses such as coronaviruses. On some Meiko appliances, the user can even set this independently. On others, the manufacturer can configure the machine to achieve this. Two temperature sensors verify each other, guaranteeing that the required temperature in the wash chamber of the Meiko machine is reliably maintained over the necessary time period (10 minutes at 80 °C, 1 minute at 90 °C). A0 values can be set or selected from 60 to 3,000.

Solid cleaning power from Winterhalter Chemicals

Winterhalter has introduced Velocity, a dishwashing chemical dispensing system that is safe, clean, efficient and environmentally friendly. Velocity uses 4kg solid detergent capsules in combination with a wall mounted dispenser to deliver an alternative to conventional liquid systems. The capsules are hermetically sealed to protect the operator during the handling process.

The Velocity dispensing system has a built-in integral rinse aid pump to give maximum cleaning performance. There are a range of detergent capsules to suit different water conditions and types of soiling. Tea and coffee stains, proteins, starches as well as fats and grease can all be effectively removed.

Designed for ease of use, the Velocity dispenser menu has three buttons for simple programming, and a rinse saver feature. The adjustable control minimises detergent overuse. The dispenser itself is compact and inconspicuous to fit into any warewash operation.

One 4kg capsule will, on average, last for an average of 900 racks.

In line with current environmental thinking Winterhalter has reduced the packaging on the capsules to reduce transportation costs and bulk. The packaging is also crushable to further cut back on the volume of waste.

Types of Warewashing include:

Under-counter machines: back bar or front-opening warewashers use smaller racks than larger machines and their performance will be lower. However, they are compact and can be fitted where they are most needed and in tight spaces

Under-counter machines: back bar or front-opening warewashers use smaller racks than larger machines and their performance will be lower. However, they are compact and can be fitted where they are most needed and in tight spaces

Pull-down hood dishwashers: The next stage up in machine design is a pull-down hood machine. These are more powerful, faster and are manually loaded with a basket of soiled tableware. They are usually configured with stainless steel tabling either side of the dishwasher so while a basket of dirty tableware is being washed, another basket of dirty tableware is being loaded ready to go in and a washed basket on the other side of the hood washer is waiting to be emptied. This gives a continual cycle of plate washing.

Rack conveyor dishwashers: These work on a pass-through system where the baskets of soiled tableware are on a conveyor belt which passes through the washing machine, going through wash zones which start at pre-rinse, go to hot wash, then hot rinse and come out on the other side of the conveyor ready for stacking away.

Flight dishwashers: These are a semi-automatic dishwashing system, similar in principle to rack conveyor systems, but very much bigger. They are designed to cope with huge volumes of soiled tableware which might be found in a university or hospital kitchen, an airline food production kitchen, large staff feeding facility or a conference and exhibition centre.

So what considerations should you take into account?

• Get expert advice! Work with rectal and knowledgeable companies that will give impartial advice and work within your budget. Explain your requirements and don’t be afraid to ask questions

• Generally, the shorter equipments washing cycle time, the lower the running costs should be

• Choose variable wash cycles that offer flexibility with washing time to suit levels of soiling

• Consider saving capabilities, water and energy efficiency and also detergent and rinse aid consumption

• Check for maintenance contracts, spare parts availability

• Shop around comparing like-for-like, and think “long-term”

• Take into account operator use, avoided if possible complicated machines that involve high levels of training and take into account your own levels of staff turnover. Make sure staff are trained and follow best practice for cleaning, maintenance, unblocking, and dosing levels

• Follow expert advice on chemicals and detergents for your machine

• Take into account where you want your equipment sited, making sure that it fits with your pattern of service and/or storage

• Take advice on water treatment, according to research hard water is responsible for that 70% of equipment failure

Meiko Launches New UPster Range

“Meiko’s launch of the new UPster series signals that this leading European manufacturer is targeting the ‘value’ end of the market,” says Meiko UK MD Paul Anderson.

“Meiko’s launch of the new UPster series signals that this leading European manufacturer is targeting the ‘value’ end of the market,” says Meiko UK MD Paul Anderson.

“I am delighted to announce the launch in the UK of the new UPster range – capitalising on those industry legends which are regarded as benchmarks for their reliability, wash quality and ease of installation.

“We are introducing these new UPster machines as Meiko’s ‘entry-level’; but we used to call them ‘Premium’. They might be the most basic machines in our range, but their build quality and heritage are truly world class and, as always, Meiko products come with the support of Meiko Technical Services and Meiko UK project management.

“The difference between Meiko UK and our competitors is about superior equipment and our quality of support before, during and after the sale.

“You can buy a machine that is probably inferior, with customer service that will never be as good as Meiko’s, for not much less that you would pay for the new UPster machines. So why risk disappointing wash results, haphazard maintenance support and a long wait for spares by looking elsewhere?”

OUTSTANDING FEATURES AND BENEFITS

Meiko is renowned for manufacturing excellence in commercial and industrial dishwashers.

For build-quality, reliability and spotless wash performance Meiko sets the standards with the best.

Meiko product is supported by Meiko UK’s award-winning technical services and a hugely experienced team of sales managers and project management.

The new UPster range comes with Meiko’s new ‘AktivPlus’ improved fine filtration system. The wash tank water is filtered not once, but now several times over. Food particles and dirt is actively and reliably ejected from the wash water by cyclical backflushing.

Blue colour-coded components on all machines except the UPster 400 glasswasher mean that cleaning is made easy. The parts coloured blue are those that need removal and cleaning in the sink as part of the regular clean down. This ensures even untrained staff instinctively know what to do.

Meiko has added an additional level of protection to help customers protect themselves. A new suction screen with an integrated dirt collection trough protects the circulation pump. Further protection is provided by another innovation, a ‘toothpick trap’ which protects the drainage pump.

WHAT’S INCLUDED IN THE NEW UPster RANGE?

Undercounter 400 x 400 and 500 x 500 glasswashers, 500 x 500 dishwasher and the UPster 500 x 500 hood machine with optional heat recovery. GiO reverse osmosis is available for all machines.

Undercounter 400 x 400 and 500 x 500 glasswashers, 500 x 500 dishwasher and the UPster 500 x 500 hood machine with optional heat recovery. GiO reverse osmosis is available for all machines.

Meiko’s UPster machines also feature improved connectivity compared to many competitor machines, because they can be connected directly to the fresh water supply without the use of intermediate safety valves.

For more information on Meiko, contact:

Meiko UK Limited, 393 Edinburgh Avenue, Slough, Berkshire, SL1 4UF

Tel: 01753 215120 E-Mail: MeikoUK@meiko-uk.co.uk

Compact, Customisable And Quick: Winterhalter’s New CTR Dishwasher

Fast, flexible, highly efficient and hygienic – that’s the latest compact conveyor dishwasher from Winterhalter. Called the CTR, it’s capable of speeds of up to 195 racks per hour and includes innovative features that reduce energy, water and chemical consumption whilst enhancing performance and wash results. The CTR is based around a clever modular system that allows options such as drying zones or prewash tanks to be retrofitted, so it can adapt to changing demand.

Fast, flexible, highly efficient and hygienic – that’s the latest compact conveyor dishwasher from Winterhalter. Called the CTR, it’s capable of speeds of up to 195 racks per hour and includes innovative features that reduce energy, water and chemical consumption whilst enhancing performance and wash results. The CTR is based around a clever modular system that allows options such as drying zones or prewash tanks to be retrofitted, so it can adapt to changing demand.

With the pressure on kitchen space ever increasing, the CTR makes use of a truly compact design. Despite its fast performance, the main wash unit is as little as 1400mm long and 800mm wide. The flexibility of the modular design and the choice of modal variants mean that a CTR system can be customised to make maximum use of available space – so it can offer the best solution, whatever the shape of the wash area. Straight lines, u-shapes, 180° outlet corner conveyor; whatever space is available, there’s a CTR configuration to fit it.

Meanwhile the modular options mean that customers can specify a system that precisely matches their needs, by adding prewash or drying zones (both of which are available in a variety of different formats) to the main wash tank.

Sustainability is an increasingly important part of the buying decision. Amongst the CTR’s impressive ‘green’ credentials is the fact that it uses up to 50% less rinse water than its predecessors. Less water means less energy is required for heating, and less chemicals for washing. There are also optional features such as the exhaust air heat recovery systems. This uses energy from the steam produced during washing to pre-heat the cold water supply. As well as reducing energy consumption, the system lowers operating costs and, by removing steam, improves the kitchen environment.

There’s no point in being energy efficient if the wash results aren’t sparkling. The CTR produces outstanding results thanks to a variety of features, including its high performance wash arms, which ensure water is distributed over the entire wash area, and the multiple water filtration system, which keeps the wash water cleaner. A new feature is the hygiene mode. If the temperature of the wash water drops, this mode automatically slows the rack speed down, ensuring a thorough, hygienic wash.

The CTR is easy to operate and look after, and can be programmed to wash dishes, glasses and utensils.

Stephen Kinkead, managing director of Winterhalter UK, says, “Compact, customisable and configurable, and delivering results that are speedier, cleaner and greener – the CTR precisely matches the needs of the modern commercial kitchen.”

List prices of the Winterhalter CTR start from £28,270.00

Winterhalter provides a total solution for dishwashing and glasswashing, from pre-sales advice to after-sales service, training and maintenance. Alongside its market-leading dish washers and glass washers, the company’s range includes utensil washers, advanced water treatment machines, cleaning chemicals and detergents.

For further details, call Winterhalter on 01908 359000, visit www.winterhalter.com/uk-en/ or email info@winterhalter.co.uk.