“Meiko already leads the market in terms of sustainability for rack transport dishwashing,” says Meiko UK MD Paul Anderson, “and Meiko has once again stunned the market by announcing massive savings on energy and water, which could not have come at a better time for UK caterers.”

Meiko previously announced in 2023 running cost savings of up to 21% for its new M-iClean undercounter dishwashers!

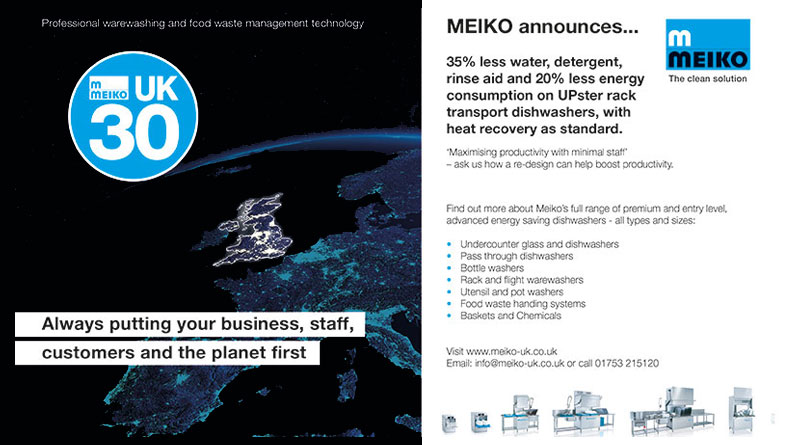

‘Maximising productivity with minimal staff’ is our theme – ask us how a re-design can help boost productivity.’

• Up to 21%* energy and up to 38%* water can be saved, (* compared to the previous model KM 280) thus reducing operating costs.

The UPster K range is what Meiko calls its ‘restaurant’ dishwasher because UPster provides top-quality cleaning with minimum space requirements. The theme of this year’s HRC stand is helping caterers combat staff shortages. Meiko’s dishwashing specialists explain how using sound design, ergonomics, and clever accessories such as tabling and sorting stations are vital to maximising productivity with minimal staff.

UPster K comes in a choice of lengths giving caterers precisely the dishwashing capacity needed, from 120 racks per hour to 150, 190 and 210.

There is maximum flexibility for dishwash design because UPster K can take a variety of shapes using powered exit and entry curves, tabling and sorting racking.

Heat recovery systems come free with UPster K because they are built in at the factory. Given sufficient air changes, no direct exhaust air connection is usually required because heat recovery effectively manages air quality.

Award-winning customer service includes commissioning always by Meiko.

At a time when operators are looking for guaranteed hygiene, combined with maximum economy and improvement to staff working conditions – the steam-free UPster machines provide the most sustainable rack transport choice